Sheet metal nesting program FieryCut

Sheet metal nesting program FieryCut includes the next main functions:

-

Geometry creation - the creation of a part geometry;

-

Sheet metal nesting - nesting optimization with increasing of sheet metal utilization coefficient;

-

CNC program generation - generation of text files with code for CNC equipment.

FieryCut is CAM application of the famous system AutoCAD. So a FieryCut user has all AutoCAD possibilities to create and edit a part's profiles. FieryCut checks a part geometry, fulfils automatic sheet metal nesting and automatic CNC-code creation.

"Geometry"

- Automatic part contours creation on the basis of AutoCAD geometry.

-

Sheet metal nesting program FieryCut with Figure option positions one contour into another contour (open or closed). Nesting level is not limited..

-

Part contours consist of lines, polylines, arcs and circles.

-

Automatic/manual geometry checking and automatic/manual geometry correction (for example, in a case of contour's intersection or contour's gaps).

-

Definition of tool entrance – with/without a lead-in.

-

Contour type changing - outside / inner.

-

Area and weight calculations.

-

Report creation (report output with information about contour number and sheet metal usage coefficient).

-

Manual contour position (without option Rectangular or Figure nesting).

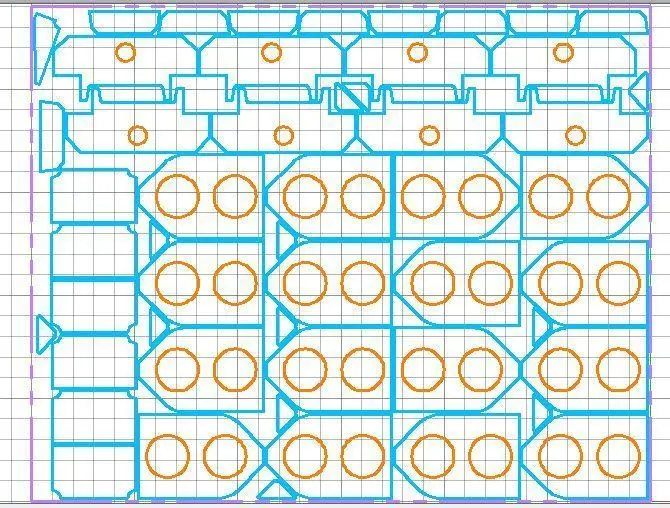

"Rectangular and figure nesting"

-

Automatic sheet metal nesting with maximum sheet metal usage coefficient.

-

Subsidiary manual part addition into a nesting map

-

Automatic and manual editing of nesting map (for example, part addition, part removal, part displacement).

-

Usage of sheet metal with different dimensions in one nesting task.

-

Part grouping.

-

Part position into holes and grooves of other parts (only with the option "Figure nesting").

-

Limitation of a suitable part rotation angle.

-

Part position with taking into account the part priority.

-

With Figure nesting option FieryCut placements any parts. The program uses holes and grooves in other parts for part placement.

- With Rectangular nesting option FieryCut placements parts without using internal holes and grooves (guillotine nesting is not supported).

Sheet metal nesting results

-

Sheet metal mapping (DXF/DWG format)

-

Sheet metal nesting report for every sheet

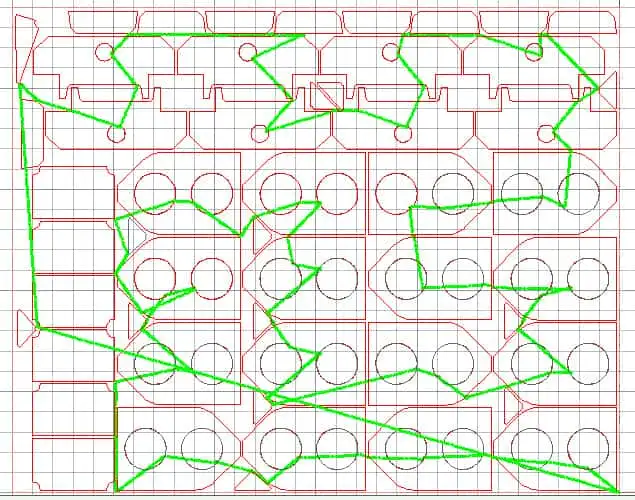

NC code generation

-

Optimized cut tool path

-

Manual editing of a part cutting sequence

-

Part cutting command editing (insert command, delete command, change lead-in point).

-

NC code generation for any types of machines (laser, plasma, water jet, oxy-fuel, etc.)

-

Calculation of in-cut time and lengths of cutting / noncutting movements

-

Cut tool movement simulation

-

Easy-to-use option for postprocessor generation*

*Sheet metal nesting program FieryCut is delivered with postprocessor for your equipment.

System requirements

|

BricsCAD |

BricsCAD 21 |

|

OS |

Windows 8 / 10 |

|

Processor |

Pentium 2000 Mhz and upwards, 64 bit (multicore processor is recommended). |

|

Operating memory |

1 Gb and upwards |

|

Monitor resolution |

1024 x 768 (1280x1024) is recommended) |

Download the Tutorial in PDF

New features added in 2018

Buy FieryCut

Now FieryCut works on BricsCAD 21 platform. It is more budget version then AutoCAD platform. There are different sets of sheet metal nesting program FieryCut (look picture)

|

5 sets |

|||||

| FieryCut-C | FieryCut-R | FieryCut-RC | FieryCut-A | FieryCut-полная | |

| Geometry | |||||

| Rectangular nesting | |||||

| Figure nesting | |||||

| NC code generation | |||||

| Old cost, ($) |

1 000 |

1 400 |

2 200 |

2 300 |

3 000 |

| New cost, ($) |

560 |

800 |

1250 |

1300 |

1700 |